About Me

I graduated from Kennesaw State University in the Summer of 2025 with a B.S. in Mechanical Engineering achieving a 3.72/4.0 GPA.

I am currently pursuing an MS in Aerospace Engineering at Florida State University with a 3.2/4.0 GPA.

My primary interest is in CAD and CFD, with a fascination for fluid-structure interaction, thermodynamics, and heat transfer.

While I have participated in undergraduate research at KSU under Dr. Sucosky investigating cardiovascular disease and Dr. Sharma investigating thermal effects under hypersonic speeds. The following portfolio illustrates the practical engineering projects that I have taken part in during my engineering journey.

Florida Center for Aero-Propulsion (FCAAP) at Florida State University

Pressure Transducer Consolidation for Low-Speed Wind Tunnel

The low-speed wind tunnel in the Florida Center for Advanced Aero-Propulsion (FCAAP) utilizes three separate pressure transducers for general wind tunnel pressure data. Each transducer individually feeds into the data acquisition system thus requiring manual observation and selection of the appropriate transducer data given the pressure ranges for optimal and precise readings. The aim of this project is to eliminate the need for manual operation with the consolidation of the three separate pressure transducers while maintaining fidelity in comparison to the original system. National Instruments (NI) LabVIEW (Laboratory Virtual Instrument Engineering Workbench) was employed as a consolidation program.

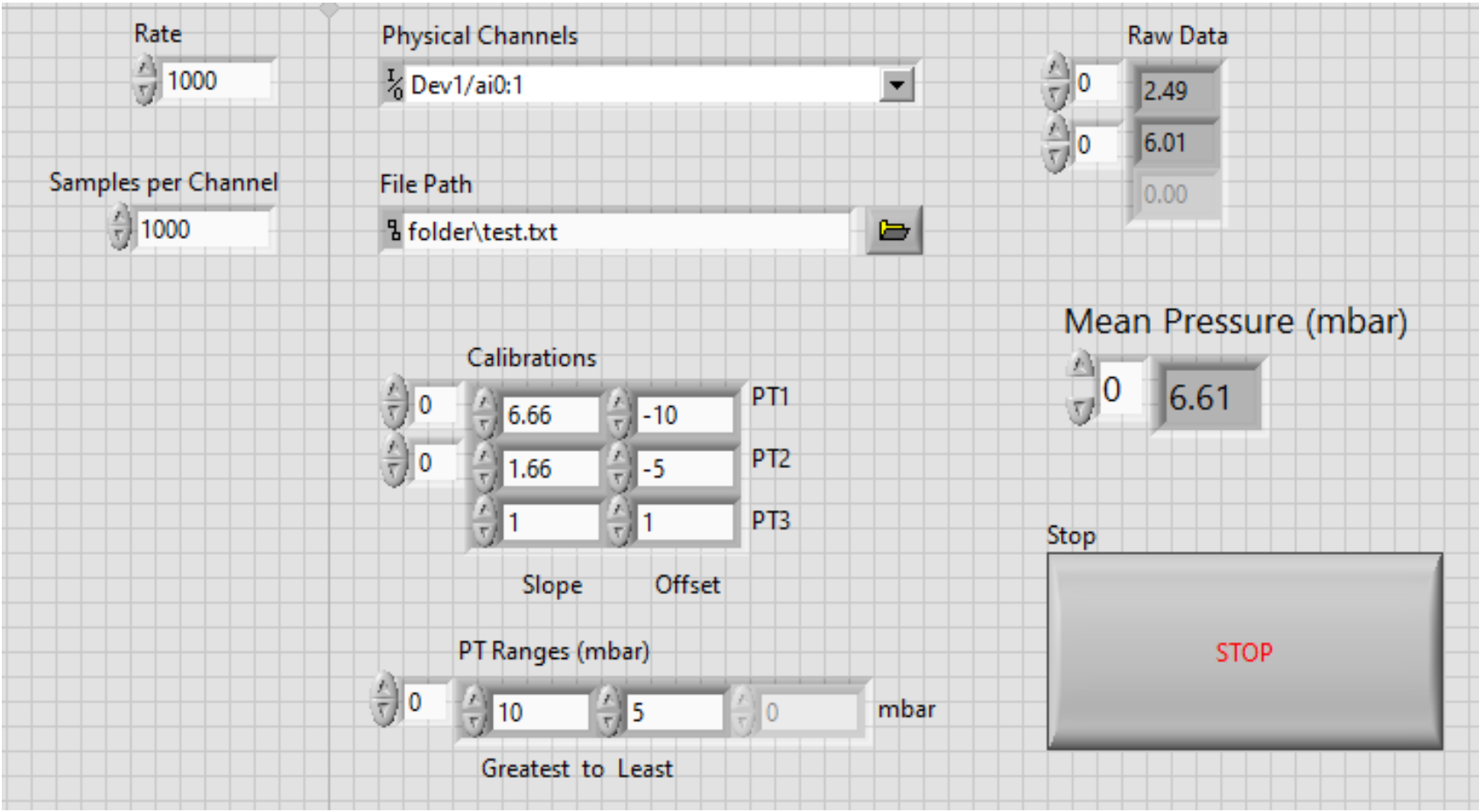

Program User Interface

Benchtop Test of the LabVIEW Program

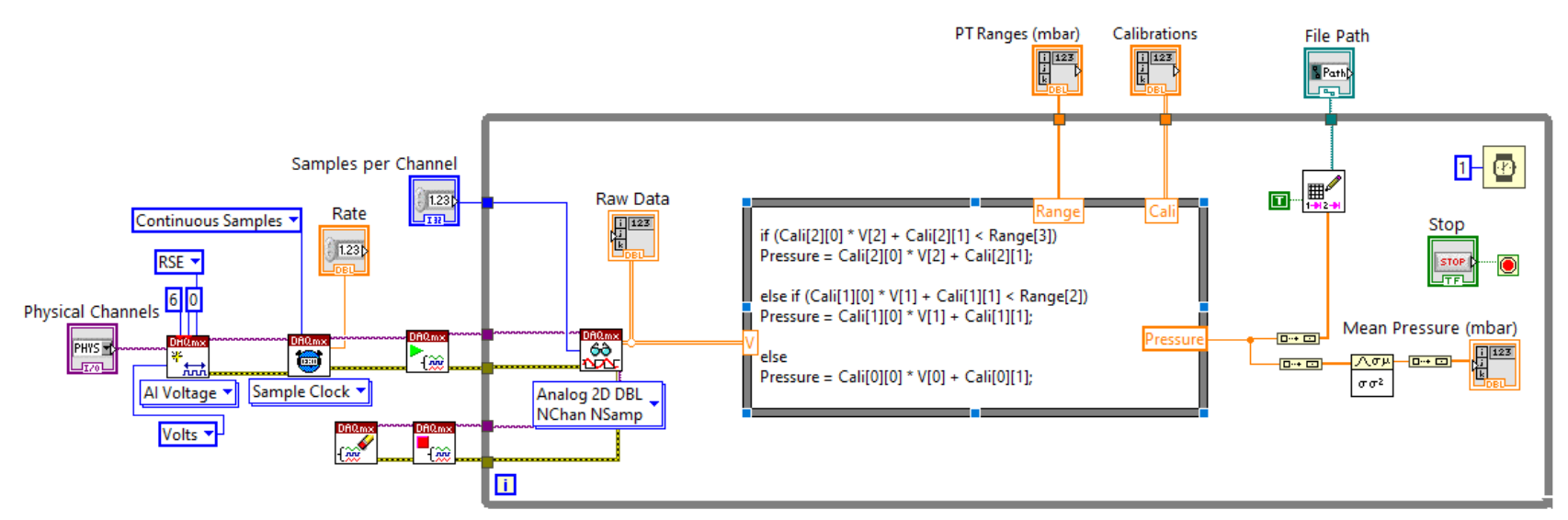

LabVIEW Program Block Diagram and Code

For the benchtop test shown below, I used two voltage inputs acting as hypothetical pressure transducers: PT1, with a range of 0–10 mbar corresponding to 1.5–3.0 VDC, and PT2, with a range of 0–5 mbar corresponding to 3.0–6.0 VDC. As the voltage of PT1 is varied and approaches or drops below 2.25 VDC (5 mbar), the output switches to PT2, since its range is more optimal in this region. Conversely, when the voltage approaches or exceeds 2.25 VDC, the output switches back to PT1.

Senior Capstone Project:

Thermoelectric Cooler Insert (TECI)

Iceless Thermoelectric Coolers already exist in the current market. However, they are expensive, inefficient, and are only capable of cooling. The goal of this project was to design and construct an insert to be used in a preexisting cooler with modularity that allows for both a “Cooling & Warming Position” and an “All Cooling Position”. A product such as the Thermoelectric Cooler Insert (TECI) would be useful for food delivery and recreational use, providing for a cheaper alternative to the traditional iceless cooler currently on the market. Over the span of a condensed 8 week summer semester, I designed the entirety of the TECI, primarily utilizing SolidWorks for CAD and simulations. This capstone project serves as a platform to represent my knowledge and expertise in CAD, computational simulations, thermal and structural theories, experimentation, and practical engineering solutions.

Cold Side of TECI

Warm Side of TECI

SolidWorks Flow Simulation utilized to validate the thermal environment of a working TECI.

Experimental set up and results for “Cooling & Warming Position”

SolidWorks FEA for the alternative use case where the TECI acts as a seat. Simulated using a distributed 500 lbf.

Generalized Bill of Materials

2025 CanSat Competition - Team OwlSat

(Finished 5th in the U.S. and 13th Internationally)

Auto-Gyro Deployment Testing

During deployment, the auto-gyro is subjected to a significant amount of force.

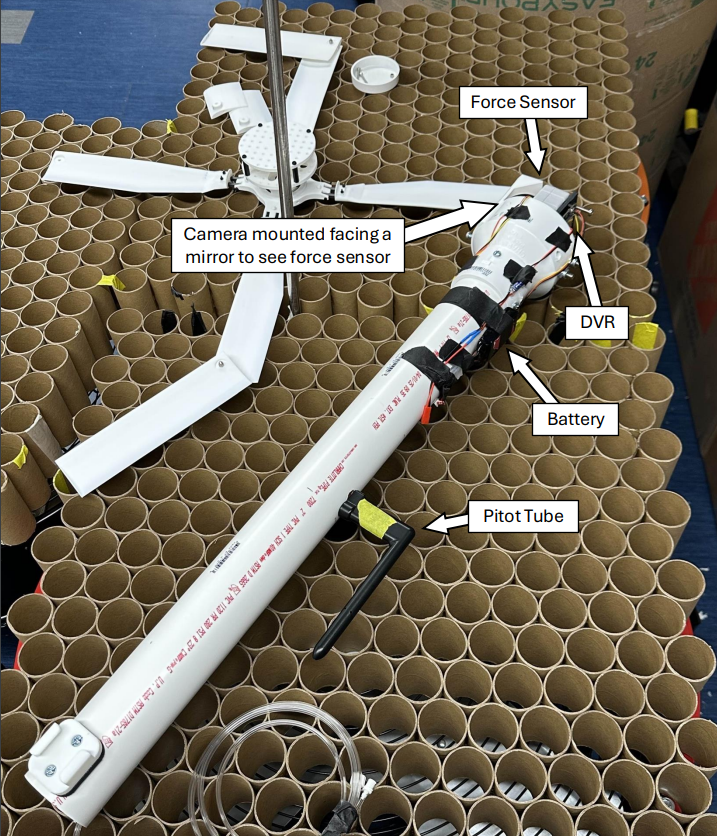

I designed a testing apparatus to simulate the environment of deployment where we used a vehicle traveling at high speeds while recording data with a force sensors and pitot tube to verify oncoming air speed.

Thanks to Atlanta Motorsports Park (AMP) for allowing us to utilize their track for a safe testing environment.

Deployment Testing Data Acquisition

(Footage of the force sensor during the deployment test at AMP)

Due to cost restraints of the project and utilizing resources available to us, our force sensor was incapable of saving or sending data. Thus, the implementation of the camera and DVR to record the force data.

In an attempt to automate the process of data acquisition, with the assistance of AI and open source Optical Character Recognition resources. I wrote code using Python that attempted to record the force data each frame of the video.

Auto-Gyro Descent Testing

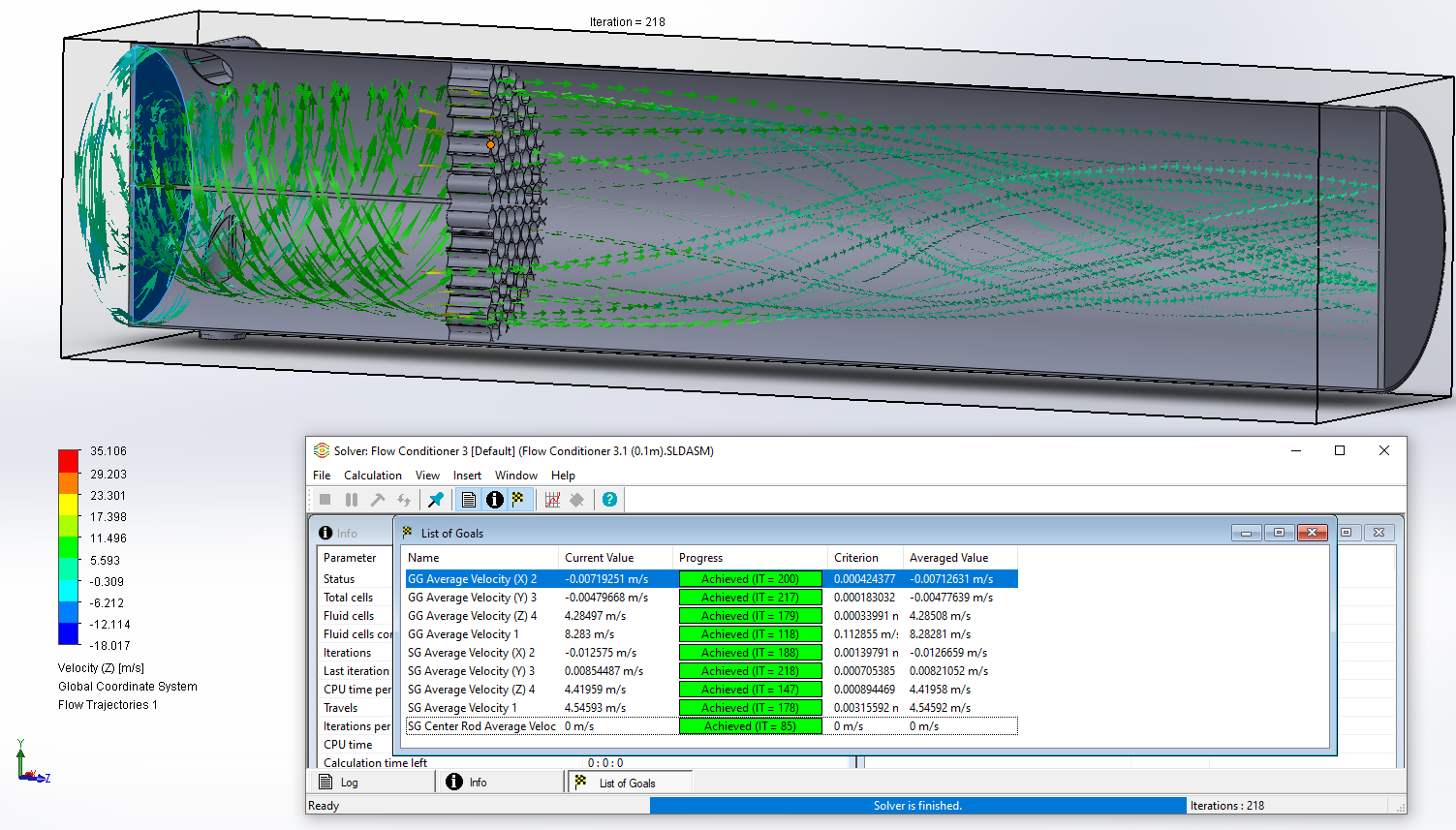

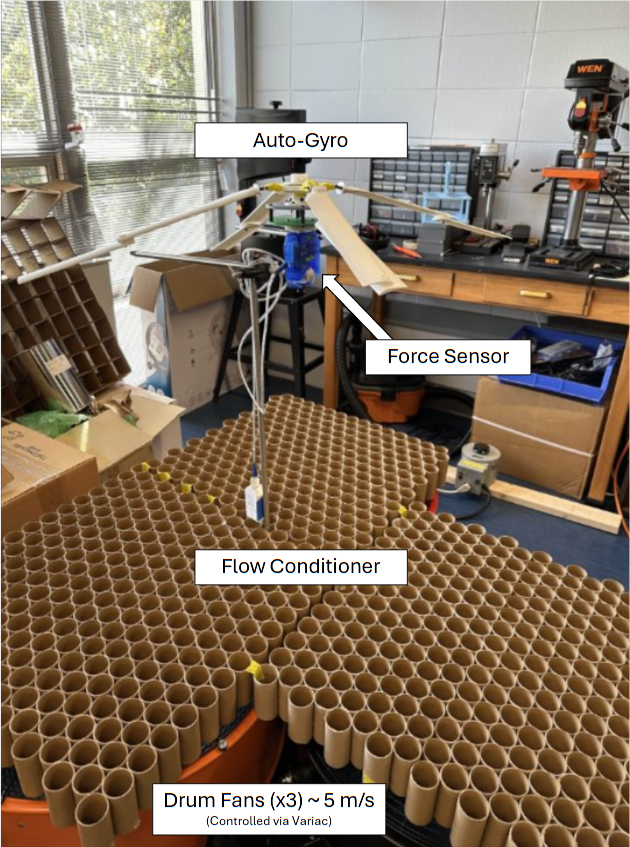

With the goal of a passive auto-gyro descent of 5 m/s. I computationally validated and constructed a flow conditioner for physical testing utilizing 3 drum fans individually controlled via a variac for precise desired wind speeds.

With the mission objective of the CanSat canister descent rate of 20 m/s. I utilized hand calculations and CFD simulations to determine the size of the parachute needed.

CFD was carried out in SolidWorks Flow Simulation where an updraft of 20 m/s was implemented and a drag force measured to match that of the weight of the canister.

Parachute Size Selection and Validation

14th Annual Pumpkin Launch

Every fall semester mechanical engineering students at KSU enrolled in ENGR 3122: Engineering Mechanics-Dynamics, take part in the annual pumpkin launch. Where in teams of 5-8 students they design and construct trebuchets to launch pumpkins.

As captain of team “Pumpkin Space Program” we achieved:

1st Place Overall

1st Place Distance & Accuracy

1st Place Design Efficiency

Our trebuchet was capable of launching a ~10lb pumpkin over 270 yards and was only $550 in build materials. (compared to the field average of ~$600)